How to identify the quality of wooden box packaging?

The luxury concept of red wine packaging wooden box

2019-11-13

What is the use of mold in the wooden box?

2019-11-22Size: The size of the high-grade wooden box meets the specified standards, and the tolerance is ≤1mm.

Supporting test: The matching with the corresponding container should not be too tight or too loose, and the looseness should be moderate. Wooden box manufacturer

Adhesive strength: The high-end wooden box joints were slightly peeled off, and the high-grade wooden box manufacturers observed whether the adhesive layer was opened or not.

Paper: The paper conforms to the type of packaging paper or contract, and the allowable range of weight: standard weight is ±10g.

Readability: Barcodes must not be read.

Molding: After the high-grade wooden box is formed, there should be no skew or deformation, and the paper should be delaminated. There should be no breakage at the fold. Wooden box manufacturer

Beer cut: the beer line and beer cut are smooth, and the upper and lower high-grade wooden lids are matched.

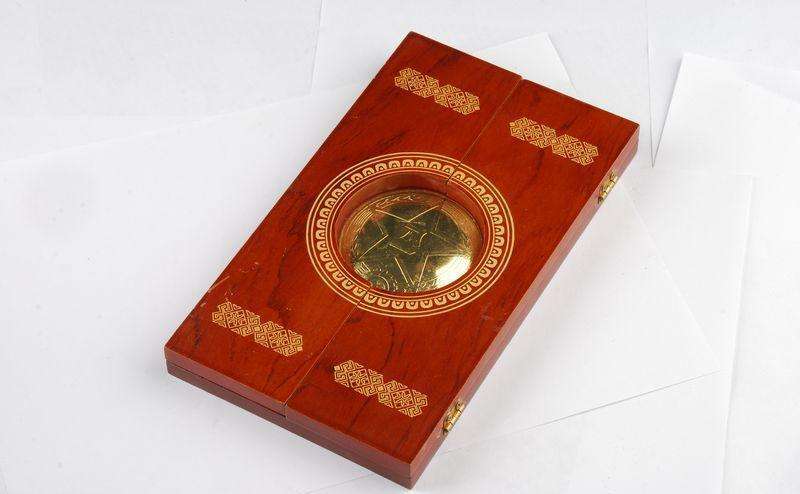

Film: High-grade wooden box surface coating, matte, plastic, etc. should be bright, uniform, no bubbles, dirt, whitening, wrinkling and so on.

Packing: The outer carton should not be dirty or damaged. When the gift box is packed, the protective paper (or bag) should be placed in the compartment.

Appearance: The surface should be smooth and flat, shiny, without obvious spots, defects, deformation, smudges, and damage. The indentation should be clear,

Color: It meets the specified color, no obvious color difference, the color of the high-grade wooden box should be consistent with the sample confirmed by both the supplier and the buyer, and the color deviation is between the upper and lower limit colors confirmed by both parties. Wooden box manufacturer

Printing: The document is accurate, the graphic printing requirements are clear, standardized, clean, the ink and ink are uniform, no burrs, no missing words, typos, no stains, layout offset less than 1mm, overprint offset less than 0.5mm, no skew, ghosting, Entire printing

The effect should be smooth and uniform, and the words, symbols, and barcodes should be clear and not clear.